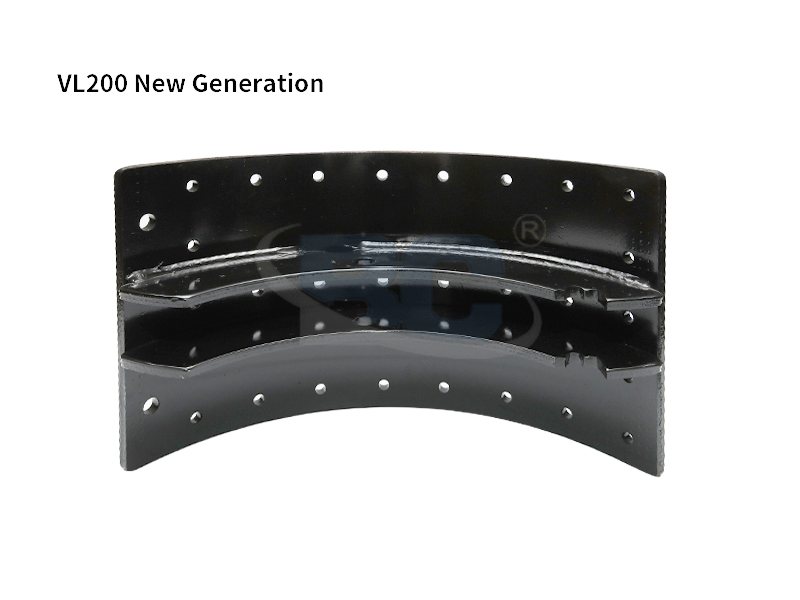

Casted Brake Shoe

A Casted Brake Shoe is an improved brake shoe design. The new design has a curved table section and at least one rib section. The table is pressed into a mold having drag and cope sections, the axis of curvature of the table section is substantially parallel to the parting plane of the mold sections, and there is no draft or parting ridge formed on the outer curved surface of the shoe. A heat-treatment process is then applied to the cast brake shoe to achieve desired mechanical properties.

The table section of the brake shoe is pressed to form a molded component. The table is made of four parts: the drag section, the cope section, and the lining. In the brake shoe, the lining is placed in the pressed-steel mold cavity and the molded parts are trimmed, polished, and shaped. Then the parts are joined together using a vulcanized resin.

Because there are no lugs on a brake shoe, the lining is mounted directly onto the cast surface. The machining operation of the outer table section is eliminated, reducing the overall production time and cost. The pressed steel core wears down with time, leading to uneven lining wear and premature relining. While a Casted Brake Shoe will not break, it will need a replacement lining sooner than a vulcanized rubber one.

A Casted Brake Shoe is an alternative to a traditional brake shoe. A vulcanized rubber-covered brake shoe has a table section that is vertically disposed. A vulcanized rubber-covered table section is used for the drag section. Unlike conventional brake shoes, a Casted-Brake Shoe is lighter and can fit a larger vehicle. The vulcanized rubber lining is more flexible, and will not break under the same amount of weight and wear.

A Casted Brake Shoe can be made using a conventional brake shoe with table sections that are mounted vertically. Prior art casting methods required a draft to be created in the mold cavities, which allowed a pattern to be cut from the molding material. However, this method of casting does not have any lugs. It is a unique solution to a common problem in automotive parts. It improves the safety and efficiency of brake shoes by making them more durable and long-lasting.

A Casted Brake Shoe is a unique type of brake shoe with a unique design and shape. It has a curved table section that is made of a hardened rubber. It also has a curved rib section that is used to stabilize the shoe. Its radial and axial alignment are essential for safe driving. A radial-shaped wheel with a casted brake shoe is also the most efficient choice for a car.

English

English 简体中文

简体中文