Zhejiang Bangchi Auto Parts Co, Ltd is an exclusive automobile Casted Brake Shoe Suppliers having been engaged in automotive brake products industry for over 20 years. They are one of the leading Brake Testing & Inspection Companies in China. They take great pride in the Quality of their products and customer satisfaction is their highest priority. By following some of the simple rules laid down by them, they help you in making the right choice in your investment. By strictly following quality system and stringent management, only a few customers can enhance product quality consistently and under all rules of IATA part number system and FMSI code of quality control.

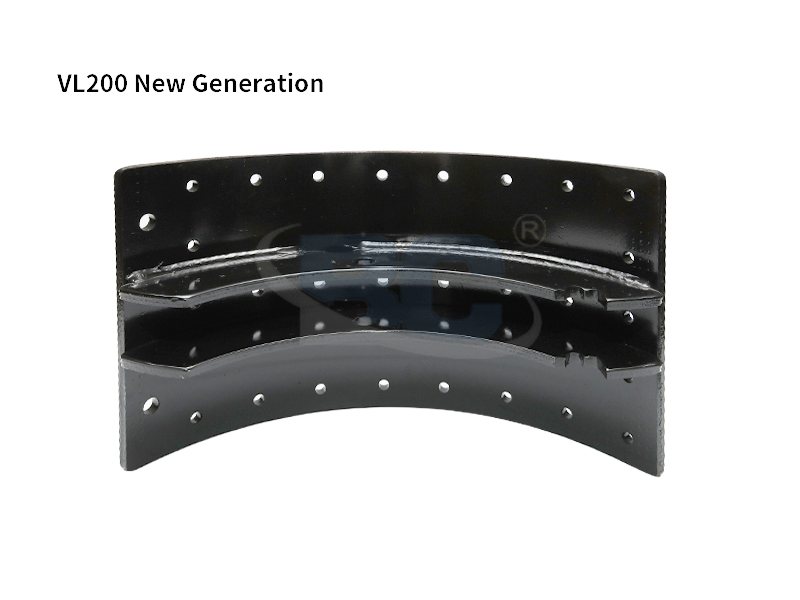

Casted Brake Shoes are of high quality and are made of heavy-duty materials. In general, the brake shoe components are made of high quality steel and aluminum. The components are tightly fitted and have to withstand extremely harsh conditions that would occur in real world driving like strong heat, extreme cold temperature variation and even vibration. The brake shoe assembly is made from cast iron with the exception of the lug nuts which are always made of chrome-plated metal. The entire assembly is then finished with a powder coat finish.

The Brake drum is another integral component of the brake shoe assembly. The drum is manufactured out of a sturdy steel called hardened steel, which is then covered with a layer of zinc. The final product is a sturdy cylindrical surface which is pressed into the center of the drum. The cylindrical surface has to endure lots of pressures and even the slight bending that occurs during the operation. A fine coating of powder is then put on the cylindrical surface to improve its pliability. Zinc helps in improving the friction resistance which reduces wear and tear.

All the product details including the specifications, features, as well as the features and benefits need to be clearly mentioned along with the picture on the packaging. There are different ways by which you can package your Brake shoes. For instance, you can either package them in shoe box or a shipping carton. You can even package them in a hardside bag.

The quality of the product is ensured using die forgings. Die forgings are very important when it comes to casted products because these help in improving the tensile strength as well as the overall strength of the product. The material used for die making includes steel, aluminum, magnesium, bronze, brass and nickel alloys. The thickness of the material used is also dependent upon the purpose for which it is intended. When the braided drum is used for racing then a thicker material should be used.

Casted brake shoe assemblies are also available in varying sizes and shapes. This helps in making sure that the proper fit is obtained for each individual customer. There are mainly two types of these drums, namely, a rotating drum and a straight shaft. The rotating drum has a cylindrical surface on which the tapered portion of the shoe is fixed. A straight shaft has a cylindrical surface that allows the tension of the spring to be properly maintained.

English

English 简体中文

简体中文